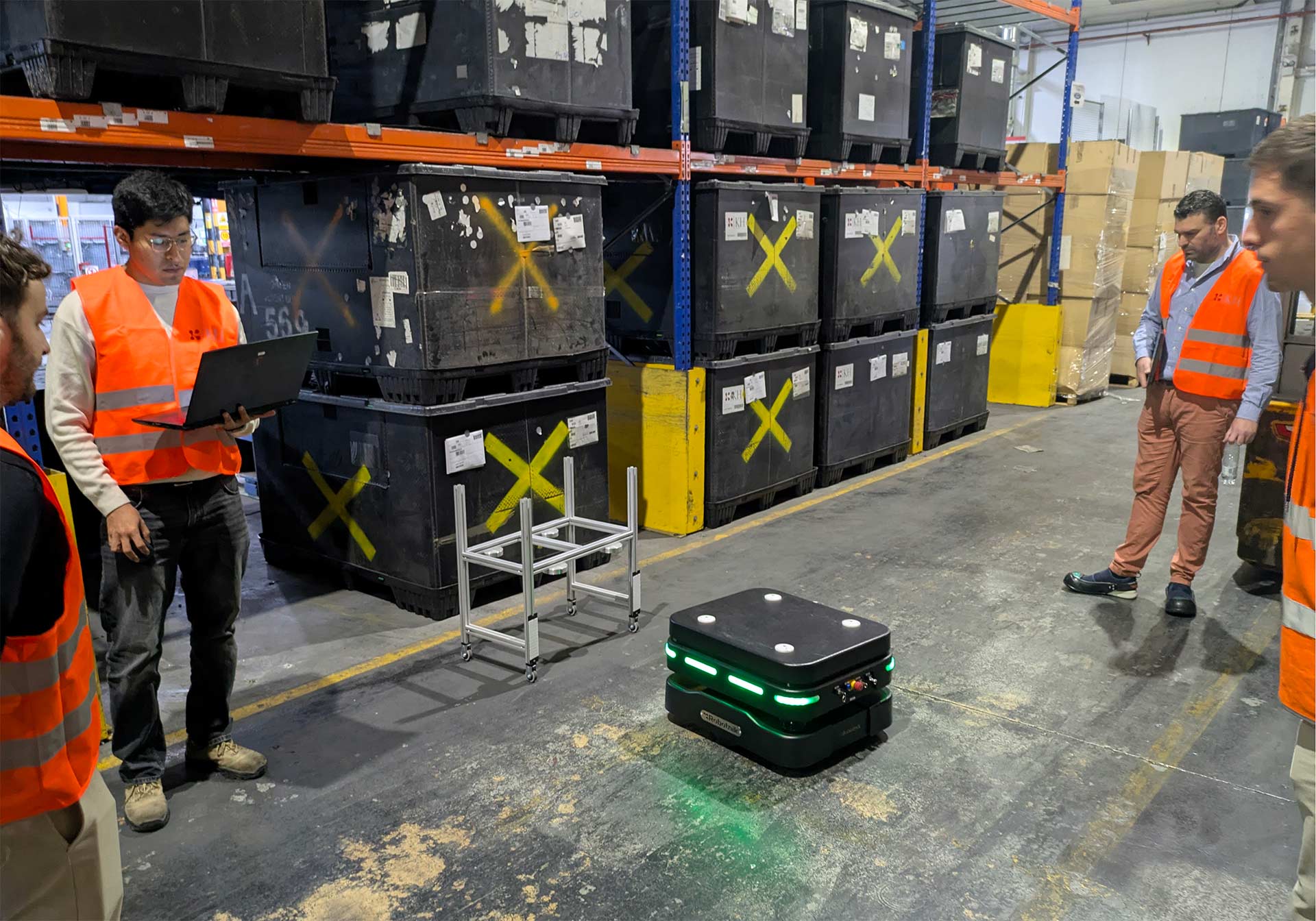

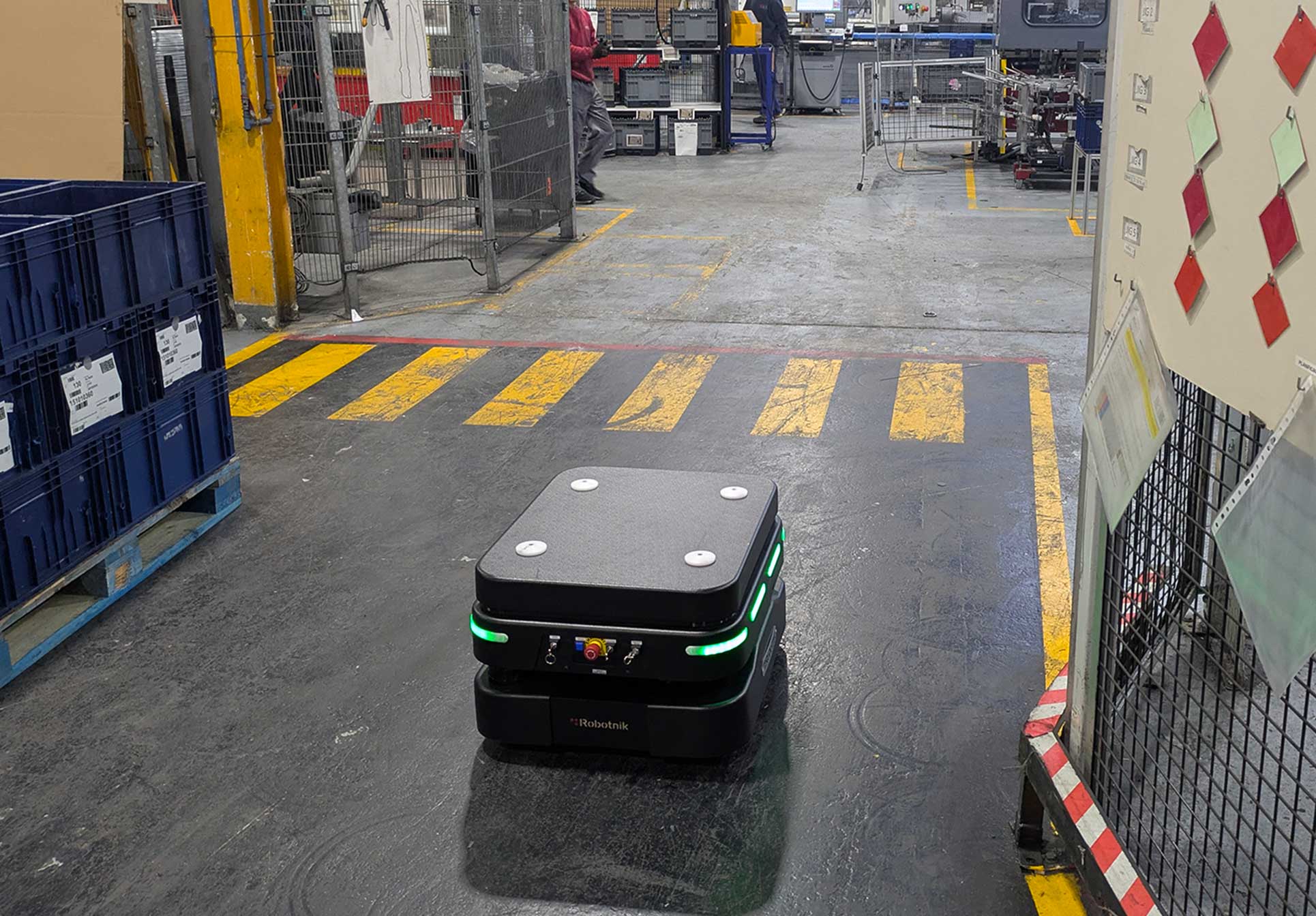

Images of the KH plant. RobotVEC plant tests with Robotnik’s AMRs.

Robot VEC

Transform your logistics.

Optimize industrial intralogistics with autonomous AMR robots and advanced simulations.

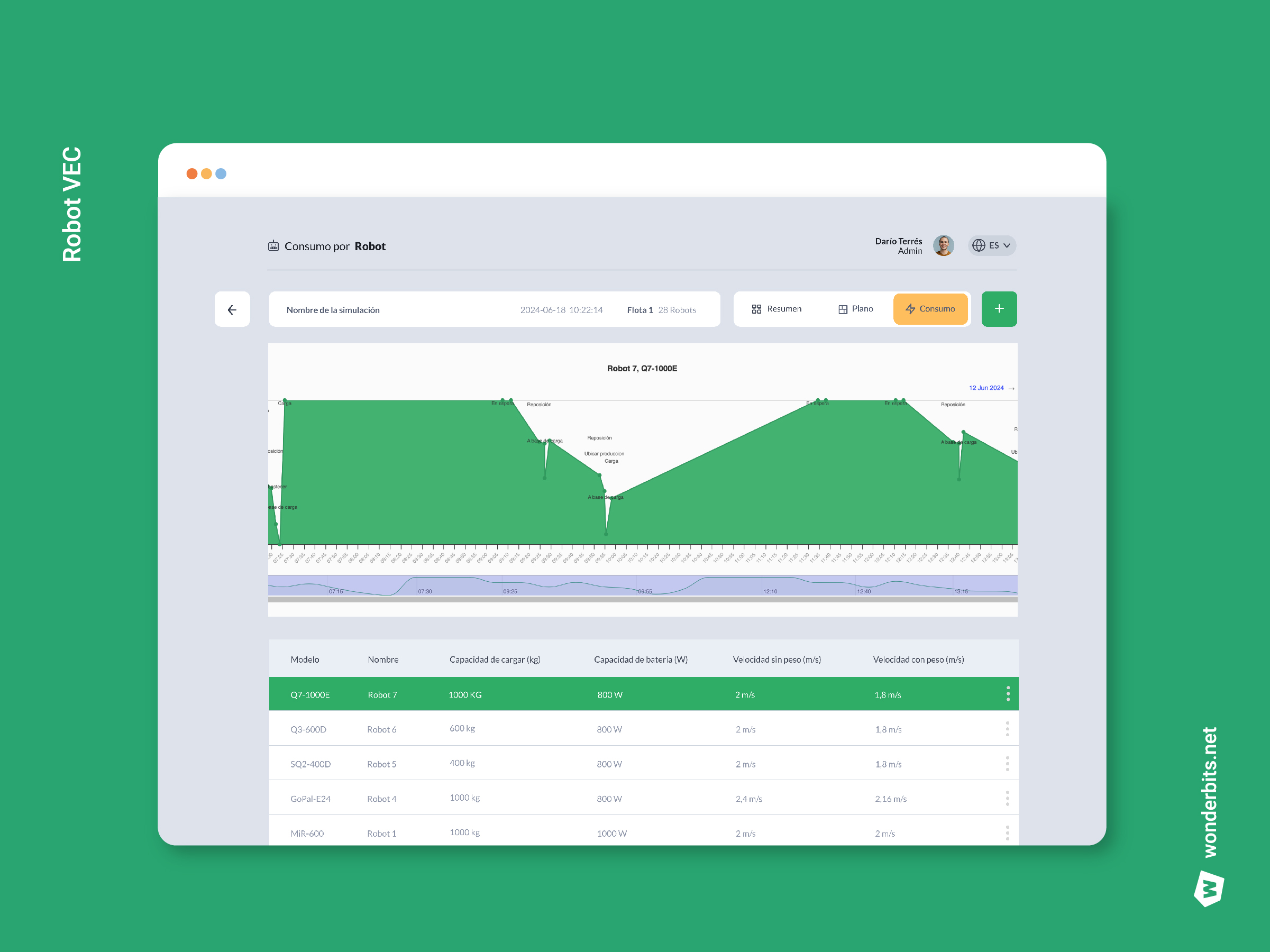

Robot VEC is a platform that optimizes industrial intralogistics with AMRs through process planning with autonomous mobile robots (AMRs). If real robots are not available, the platform allows the creation of simulations via a digital twin of the plant, enabling the evaluation of automation. Additionally, it provides detailed information about the optimal fleet required for efficient operations, helping make informed decisions before implementing any changes, all based on real data.

Key Features

Flexible Integration

Compatible with any robot on the market, allowing the creation and management of customized fleets tailored to each client’s specific needs.

Advanced Simulation

Process real data from systems such as ERP, MES, and WMS, and create simulations with digital twins to optimize task planning and execution.

Scalability and Efficiency

Designed for environments of various sizes, significantly improving synchronization and productivity of operations.

Visualization and Control

Offers tools to monitor order history, battery usage, and operations, facilitating data-driven decision-making.

Economic Impact

Reduction of Operational Costs

Optimization with autonomous mobile robots (AMRs) improves efficiency in repetitive tasks, allowing personnel to be redirected toward more strategic activities. Automation reduces human errors, generating savings and freeing up resources for higher-value areas within the company.

Productivity Improvement

AMR robots operate continuously, increasing material handling efficiency within the plant and reducing waiting times. Additionally, the platform simulates movements and calculates operation times to ensure that robots follow the fastest and most efficient routes, maximizing available time usage.

Energy Savings

With an optimized fleet of robots, energy consumption is reduced by managing routes and battery usage more efficiently, contributing to better resource utilization.

Space Optimization

Optimizing internal flows and reconfiguring the plant layout to incorporate robots helps free up useful space, which can lead to significant savings in storage and facilitate future expansions.

Scalability

The flexibility to create customized fleets according to client needs allows costs to be adjusted based on plant size and work demand, facilitating technology integration without requiring high initial costs.

Public-Private Collaboration

Robot VEC is based on a public-private collaboration developed alongside our partners at KH, a leading company in the production of components and services for the automotive industry. This platform focuses on strengthening the value chains of Spain’s automotive sector, a strategic and fundamental industry for the country’s economy and technological development.

Digital Transformation of the Automotive Industry

The primary goal of the project is to drive the digital transformation of the automotive industry, adapting it to the challenges of sustainability and global competitiveness. It also aligns with the European Union’s objectives of digitalization and sustainable innovation. WonderBits has been funded by the Recovery, Transformation, and Resilience Plan, as well as by the EU through the NextGenerationEU program, reinforcing its commitment to modernizing industrial infrastructures.

Electric and Connected Vehicle

Since 2022, WonderBits has been actively participating in the ECOMOVIL23 consortium as part of the Strategic Project for Economic Recovery and Transformation (PERTE) of the Electric and Connected Vehicle. This project seeks to consolidate European leadership in automotive sustainability and technology, while contributing to the creation of quality jobs and the development of a more resilient economy.

The PERTE for Electric and Connected Vehicles is aligned with the EU’s goals to achieve climate neutrality, foster strategic investment, and promote a greener, more digital Europe.

Request a Free Demo

Discover how Robot VEC can revolutionize intralogistics in your industrial plant.

Services

Ai, Blockchain, Design, Development

Date

3rd of December, 2024