In a context where efficiency, sustainability, and competitiveness are key factors for the industry, companies need technological solutions that optimize their resources and ensure their effective use. Intralogistics, a critical area in the value chain, demands advanced systems capable of efficiently managing transportation and storage tasks within plants. Innovation at the service of intralogistics, in this scenario, Robot VEC emerges as an innovative and transformative solution.

Do you want to discover how to optimize resources and improve management in your plant?

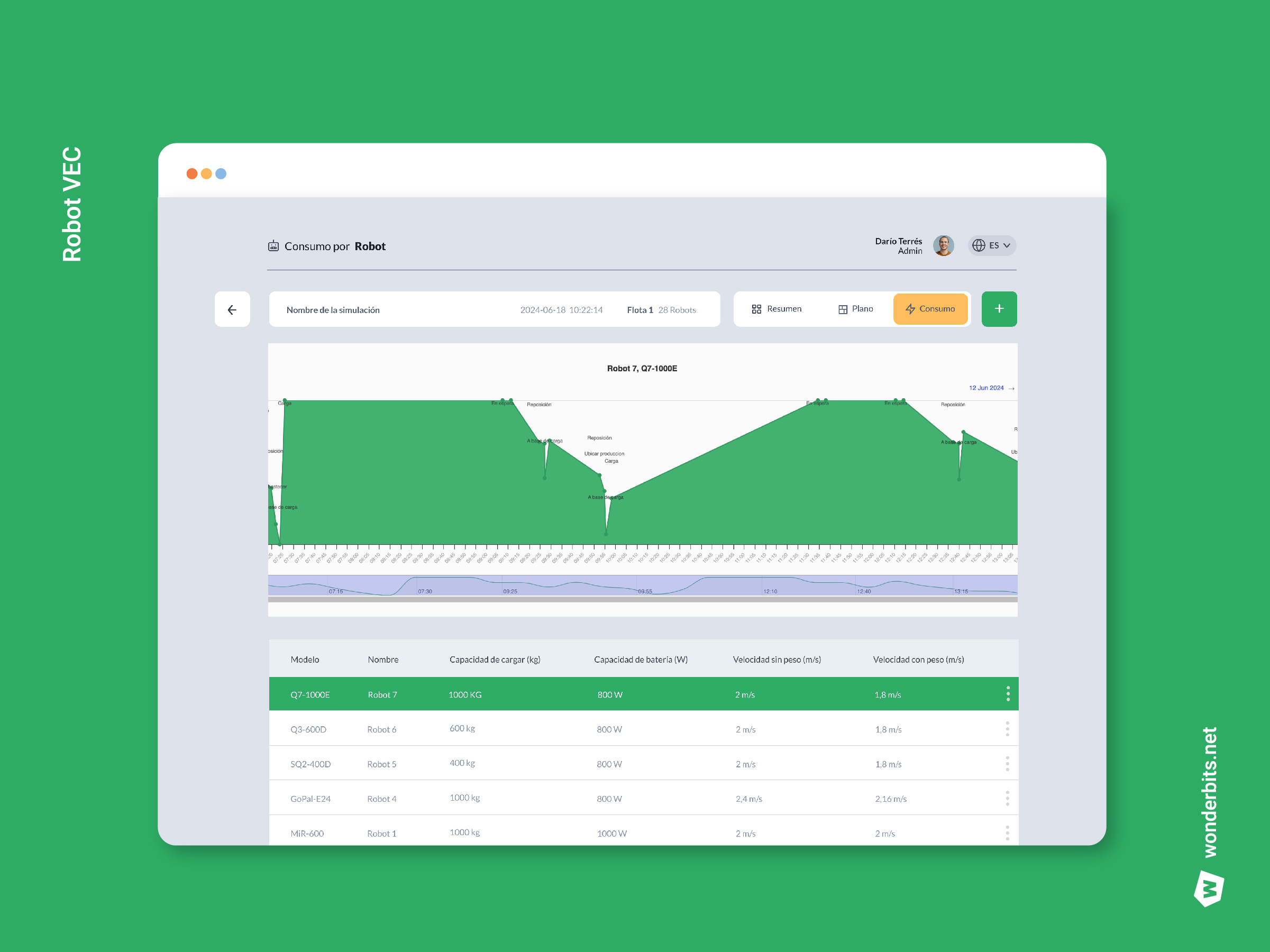

Robot VEC allows you to plan processes with autonomous mobile robots (AMRs) to maximize efficiency. If you don’t yet have real robots or are considering adding more to your plant, you can simulate operations using a digital twin. This enables you to evaluate the impact of automation and gather insights about the optimal fleet for your operations. By doing so, you can make data-driven decisions before proceeding with any implementation.

Key Features

Significant Increases in Operational Efficiency

Robot VEC optimizes operational efficiency by reducing internal transportation times and optimizing routes. The platform allows for the creation and management of customized fleets tailored to each client’s specific needs, improving operational synchronization and optimizing workflow. Additionally, it provides detailed planning of operational processes, whether with real or simulated robots, ensuring efficient management and minimizing inefficiencies.

Resource Optimization

It facilitates the more efficient use of equipment and personnel to maximize productivity, thanks to advanced simulation that processes real data from systems such as ERP, MES, and WMS. These simulations enable more precise task planning and execution, ensuring that resources are optimized and allocated appropriately. The system’s scalability and efficiency also allow it to adapt to environments of various sizes, improving operational synchronization and overall productivity.

Greater Sustainability

Robot VEC allows monitoring of order history, battery usage, and operations, making it easier to make data-driven decisions to improve efficiency and reduce environmental impact. By using a digital twin, clients can analyze long-term performance and make adjustments to minimize resource and energy use. The system’s scalability ensures it can adapt to different operation sizes, optimizing resource use as the company grows.

Based on public-private collaboration

Robot VEC is based on the public-private collaboration we have developed with our partners at KH, a leading company in the production of components and services for the automotive industry.

The main goal of the Robot VEC project is to drive the digital transformation of the automotive industry, adapting it to the challenges of sustainability and global competitiveness, in line with the European Union’s objectives of digitalization and sustainable innovation. Since 2022, WonderBits has actively participated in the ECOMOVIL23 consortium as part of the PERTE for the Electric and Connected Vehicle, a project aimed at consolidating European leadership in sustainable automotive technology while fostering the creation of quality jobs and a resilient economy. Funded by the Recovery Plan and the NextGenerationEU program, this effort reaffirms WonderBits’ commitment to industrial modernization and sustainability.

WonderBits: Innovation in every step

At WonderBits, we don’t just create technology; we design solutions that address the real challenges of the industry. Robot VEC is a perfect example of how innovation can drive productivity and sustainability. We are committed to providing tools that not only solve current problems but also prepare businesses for the future.

Join the intralogistics revolution

Request a free demonstration and discover how Robot VEC can revolutionize intralogistics in your industrial plant. Contact us for more information about this project and learn how WonderBits can be your strategic partner in digital transformation.

Explore more about Robot VEC on our portafolio.